Everything you need to know about shaft grounding devices

As the world becomes more reliant on technology, electrical equipment and rotating machinery continue to grow in popularity. However, with the increase in usage and complexity of such machinery, there arises a need to ensure their safety and functionality. This is where shaft grounding devices come in. These devices provide a safe and effective way of grounding rotating machinery to prevent electrical discharges that could damage the system, endanger personnel, or potentially cause catastrophic failures.

It is crucial for industries to be well-informed on the different types of shaft grounding devices available, how they operate, and best practices for their installation and maintenance. In this blog post, we’ll dive into everything you need to know about shaft grounding devices, their various capabilities, and the standards and guidelines that govern their use. We’ll also discuss the importance of regular maintenance and testing to ensure their continued effectiveness and reliability.

1. Introduction to shaft grounding devices and their purpose in protecting rotating machinery.

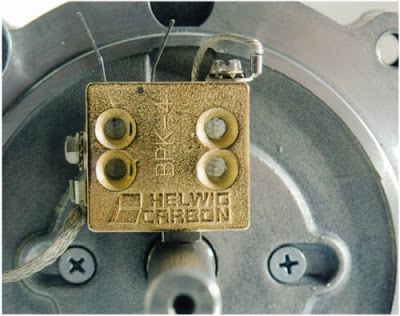

Shaft grounding devices are essential components in the operation of rotating machinery. These devices are designed to protect the machinery from electrical discharge, which can occur as a result of uncontrolled electrical currents or static buildup in the system. When electrical discharge occurs, it can cause significant damage to the machinery, resulting in downtime and costly repairs. The purpose of shaft grounding devices, also known as grounding brushes or bearing protection rings, is to prevent these discharges from occurring by providing a low resistance path for any electrical currents that may exist in the system. In this document, we will provide a comprehensive overview of shaft grounding devices, including their purpose, how they work, and their importance in ensuring the efficient and safe operation of rotating machinery.

2. The different types of shaft grounding devices available in the market, including their features and functions.

Shaft grounding devices are essential components in rotating machinery systems that are susceptible to stray currents and electrical damage. These devices ensure that any stray currents generated in the rotating machinery are intercepted and safely transferred to the ground, thus protecting the system from bearing damage, motor failure, and other adverse effects. There are several different types of shaft grounding devices available in the market, each with unique features and functions. These include conventional grounding brushes, non-contact shaft grounding rings, and hybrid grounding solutions. Conventional grounding brushes provide a low-resistance path to the ground, allowing any stray currents to be easily discharged. Non-contact shaft grounding rings, on the other hand, use induction to generate a reverse current, effectively neutralizing any electrical charge buildup between the shaft and the bearings. Hybrid solutions incorporate elements of both conventional and non-contact shaft grounding devices to provide a more comprehensive and effective grounding solution. Each of these devices has its own set of advantages and disadvantages, depending on the specific application and use case. Understanding these differences is key to selecting the right shaft grounding device for any given system.

3. The benefits of using shaft grounding devices, including improved equipment reliability, reduced downtime, and lower maintenance costs.

Shaft grounding devices, also known as shaft earthing devices, play a crucial role in the reliability and maintenance of rotating equipment. These devices are designed to divert electrical currents away from the bearings and the equipment housing, preventing damage from electrical discharges. Apart from protecting the equipment, shaft grounding devices offer several benefits to the users. Improved equipment reliability is perhaps the most significant advantage of using shaft grounding devices. By reducing the risk of electrical damage, equipment uptime can be maximized, avoiding costly repairs or replacements. Furthermore, reducing downtime is also a benefit of using these devices. Less downtime means less lost production, resulting in higher output and greater profits. Finally, shaft grounding devices can also lead to lower maintenance costs by reducing wear and tear on critical parts of the equipment, resulting in lower repair and replacement costs. In conclusion, the adoption of shaft grounding devices offers a significant return on investment, with improved equipment reliability, reduced downtime, and lower maintenance costs.

4. Important considerations when selecting a shaft grounding device, such as the type of machinery, the environment, and installation requirements.

When selecting a shaft grounding device, there are several important considerations to keep in mind. The first consideration is the type of machinery that the device will be installed on. Different types of machinery may require different grounding device designs to ensure maximum effectiveness. Additionally, it is important to consider the environment in which the machinery will be operating, as factors such as humidity, temperature, and vibrations can impact the performance of the grounding device. Finally, it is important to carefully review the installation requirements of the device to ensure that it is installed correctly and that the grounding device is properly grounded to prevent any electrical hazards. Overall, these considerations are critical in selecting an effective shaft grounding device that will ensure safe and reliable operation of the machinery.

5. Best practices for installing and maintaining shaft grounding devices to ensure optimal performance and longevity.

Shaft grounding devices are critical components in various applications, including motors, generators, pumps, and compressors. They help to prevent bearing damage and resultant equipment failure due to shaft voltage and current circulating in rotating machinery. To ensure optimal performance and longevity, it is essential to install and maintain these devices using best practices. In this article, we will outline five such practices that will help you get the most out of your shaft grounding devices. By following them, you can minimize downtime, decrease repair costs, and enhance the overall reliability and efficiency of your equipment.

In conclusion, shaft grounding devices play a crucial role in protecting electrical equipment from electrical currents that can damage bearings, rotors, and other components. Understanding the different types of shaft grounding devices, their benefits, and how to properly install and maintain them is essential for ensuring optimal performance and long-lasting operation of electrical equipment. With the right knowledge and use of appropriate shaft grounding devices, businesses can keep their equipment running smoothly, reduce maintenance costs, and avoid downtime due to electrical failure.

Megjegyzések

Megjegyzés küldése